Wooden Cross Ties use fasteners to hold the rail plates or rail fasteners in place. The use of “spikes” (dog spikes) or Tirefonds (screw spikes)are used by railways. Most countries outside of the USA use Tirefonds or screw spikes. As a direct result of track use, the Tirefonds in cross ties get loose. When the Tirefond is loose, the rail will move and the track becomes “out of gauge”, particularly in the curves where big loads are experienced. Also, rain water can seep into the loose area which promotes “tie rot”. The above two things can result in a wooden cross tie to become “worn out” and need to be replaced or at least the Tirefond re-inserted.

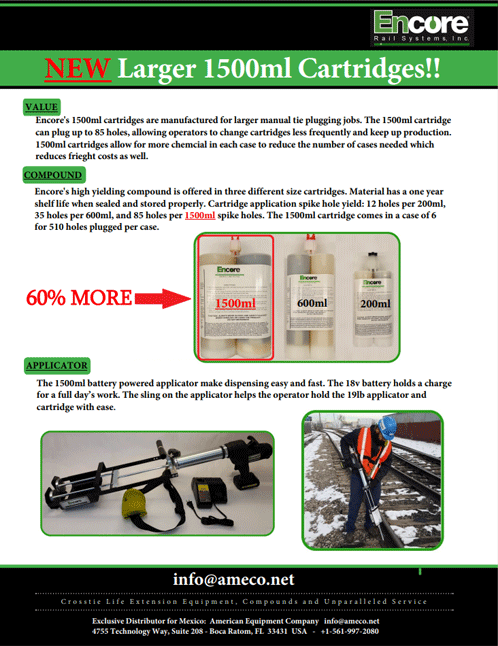

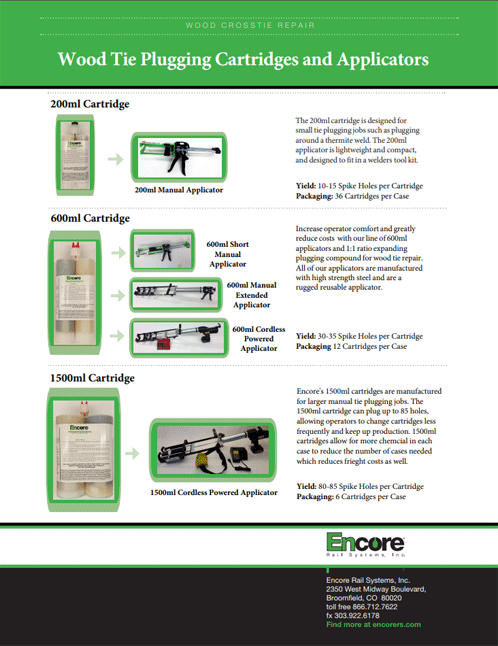

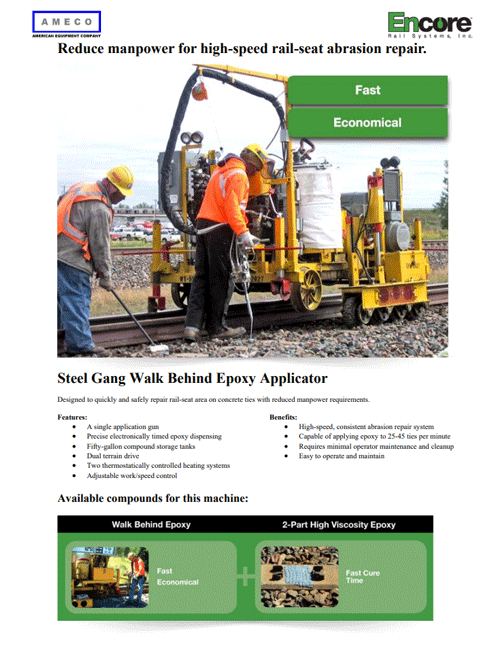

AMECO supplies a product from ENCORE Rail Systems, Inc. which is a custom designed Resin (compatible to the type of wood in use) that is inserted into the hole of the wooden tie during rail or tie renewal or rail welding activities. The Resin is inserted either manually or via a track machine, whereby the hole is filled and receives a new Tirefonds drilled into the cross tie as if it were a new hole. Concrete Ties suffer from rail seat abrasion. ENCORE produces an Epoxy that forms a cushion for the rail seat to rest which prevents abrasion to the concrete tie surface. Abrasion creates premature wear. The Epoxy can be manually or automatically placed on the concrete tie.Call us today 08 9249 4220